The MiG-15 is a highly-capable clear-weather interceptor and light ground attack aircraft that saw much action in both the Korean and Vietnam Wars. Known as “Fagot” to NATO and “Type 15” to the USSR, it was the first swept-wing jet fighter to come out of the Mikoyan-Gurevich stable in the late 1940s. The MiG-15 served in large numbers during the 1950-53 Korean War, where its maneuverability and high transonic speed made it superior to all UN aircraft except the F-86 Sabre. The MiG-15 is credited with the first ever air-to-air jet kill, downing a USAF F-80C Shooting Star on November 1, 1950.

The DCS variant is the improved MiG-15bis ("second") type, which entered service in 1950 with a Klimov VK-1 engine giving it an effective top speed of Mach 0.92 (685 mph)

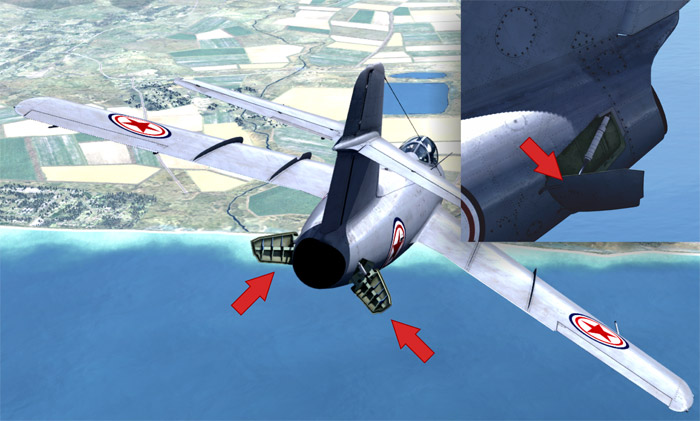

A powerful 37mm autocannon in the lower right fuselage (40 rounds total) and 2 × 23mm autocannon in the lower left fuselage (80 rounds per gun, 160 rounds total) give the MiG-15bis tremendous punch. In the secondary light ground attack role, the Fagot can also carry 100 kg bombs or rocket pods on its twin underwing hardpoints.

On 23 October 1951, 56 MiG-15bis intercepted nine B-29 Superfortresses escorted by 34 F-86 Sabres and 55 F-84E Thunderjets. Despite being outnumbered, the Soviet-piloted MiG-15s shot down/and or seriously damaged eight B-29s and two F-84Es, losing only one MiG in return, leading the Americans to call that day "Black Tuesday".

Some 18,000 MiG-15s were built and served in every nation under the Soviet sphere of influence during the Cold War and on into the 21st century. Battle the equally superb DCS: F-86 Sabre and see who comes out on top.

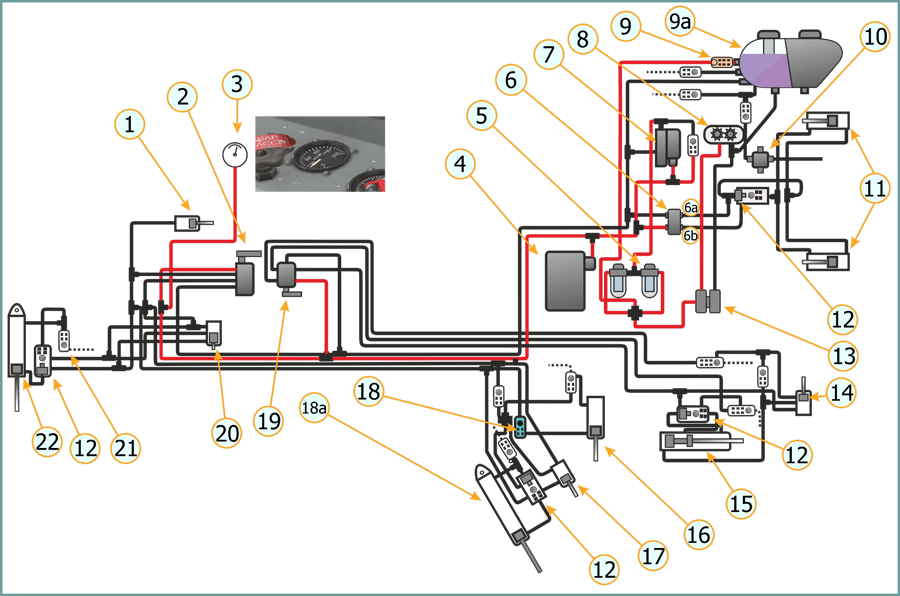

The MiG-15bis is equipped with a 28.5 VDC single-circuit electrical power system. Power sources include a single 12A-30 battery and a ГСР-3000 (GSR-3000) generator with a 3.0 kW power output capacity. Both power sources are connected to a single bus.

Because the airplane is not equipped with an AC power system, each consumer requiring AC power is equipped with an individual inverter (115 V and/or 36 V).

In case of generator failure, the battery supports aircraft flight in daytime and in cloudy conditions for 24-26 minutes or 20-23 minutes at night.

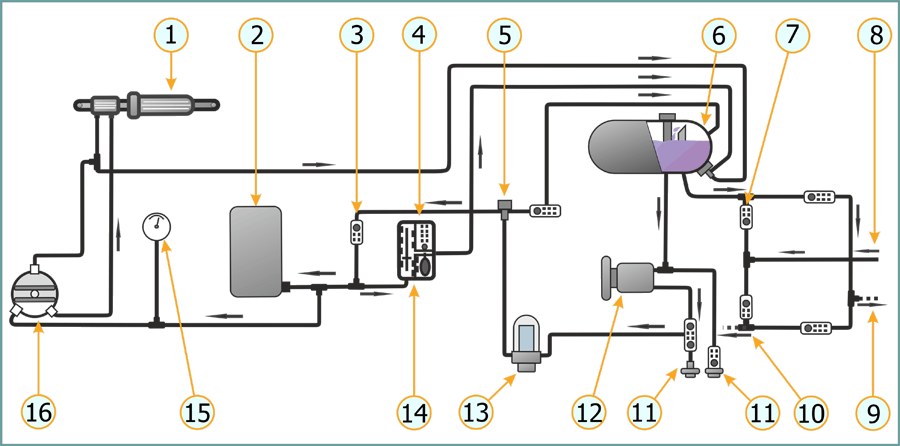

The utility hydraulic system provides:

The lateral control hydraulic system is designed to reduce the stick forces required for lateral flight control (roll). The system is completely independent from the utility hydraulic system (separate hydraulic tank and pump). The system supplies hydraulic fluid to the hydraulic booster under constant pressure to actuate aileron control.

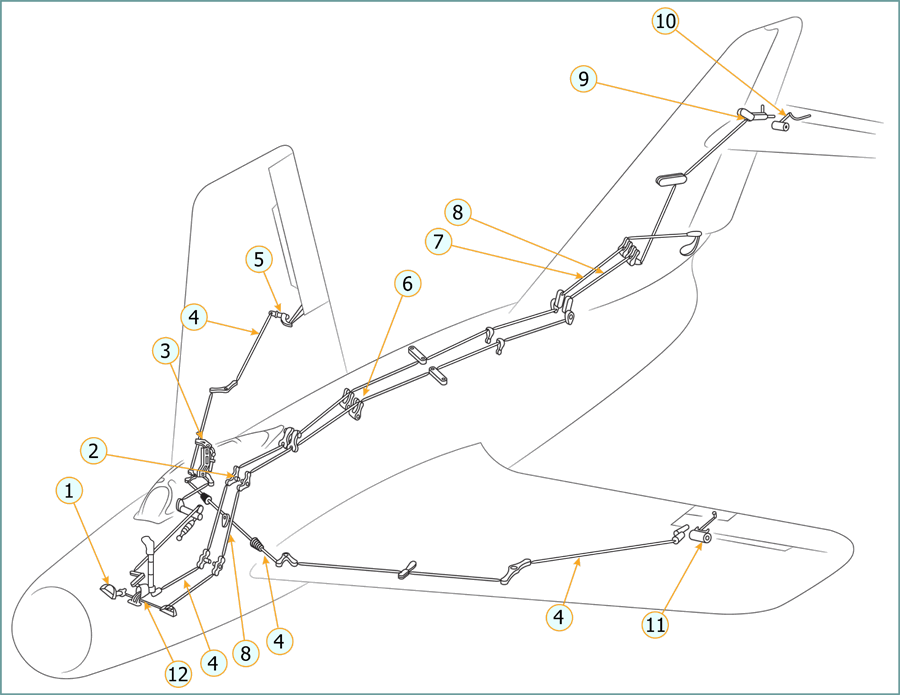

In the 1950s the concept of an aircraft's flight control system included not only controls associated with pitch, roll, yaw, and engine control (stick, pedals, throttle, trimmers), but also flap and airbrake controls.

The flight control system includes cockpit controls, associated control surfaces, and the linkages between them.

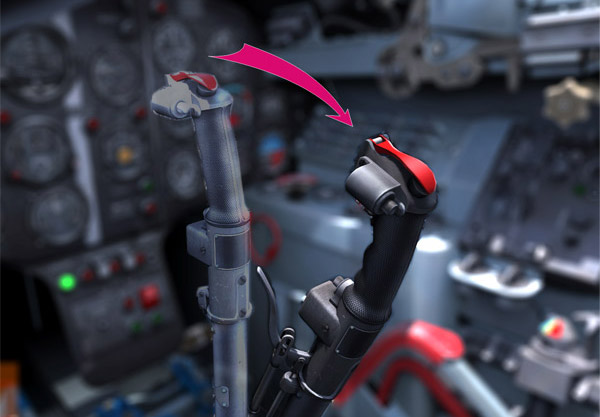

Elevator (pitch) control: accomplished by pushing and pulling the flight control stick forward and aft (pulling aft in the image below):

Elevator trim control: accomplished using the elevator trim control switch on the left side of the cockpit via an electrical trim control motor installed in the stabilizer spar.

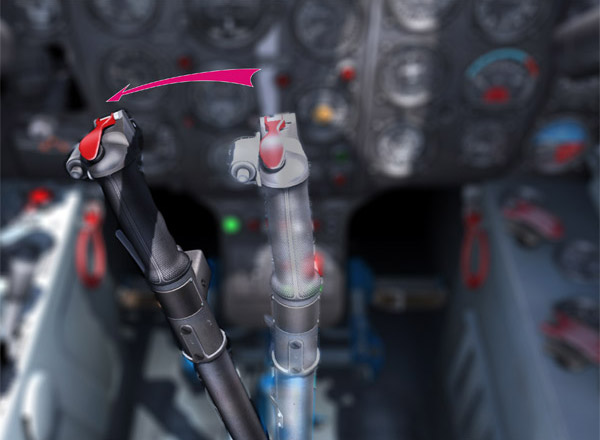

Aileron (roll) control: accomplished by deflecting the flight control stick to the left or right (left in the image below):

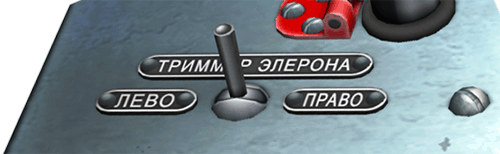

Aileron trim control: accomplished using the aileron trim control switch via an electrical motor installed in the left wing rear beam.

Rudder (yaw) control: accomplished by pushing the left or right pedal (for left or right yaw, respectively) (left pedal application shown in image below):

Forward pedal travel is limited to 29° from the neutral position. At this limit, rudder deflection amounts to 20°.

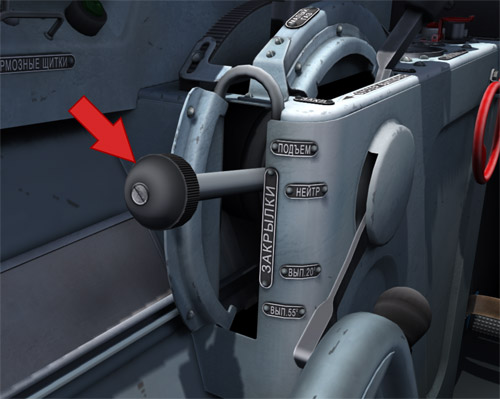

Flap control: accomplished using the flap control handle arranged vertically at the rear of the left cockpit console:

The flaps are installed on the wings between the ailerons and the fuselage. Flaps are extended to their maximum position of 55° when landing. For takeoffs, flaps are set to the intermediate (takeoff) position of 20°.

Airbrake control: The airbrake can be extended either by pressing the airbrake button on the control stick (for short use while the button is held down) or setting the airbrake switch on the left cockpit console to the OPEN (forward) position for longer use (for example when diving).

The airbrakes open to an angle of 55°±1°. Movement of the airbrakes from the closed position is indicated by the airbrake caution light on the left cockpit console, which is connected to a microswitch on the right airbrake paddle.