The Focke-Wulf Fw 190D ‘Dora’ was a fast, versatile and powerful World War II fighter and ground attack aircraft. Twin 20mm Mauser MG-151/20 cannon in the wing roots with 250 rounds per gun and twin 13mm MG-131 cannon with 475 rounds per gun in the nose cowling give the Dora a fearsome punch. It is also able to carry one 500 kg (1,020 lb) SC 500 bomb in the ground attack role.

A development of the successful Fw 190 A, the D-9 entered Luftwaffe service late in 1944. The supercharged Junkers Jumo 213 V-12 engine with MW-50 injection system boosted the Dora’s emergency power from 1,750 hp (1,287 Kw) to 2,100 hp (1,508 Kw), making it a match for the P-51D Mustang fighters escorting Allied bombers in raids over Germany. Even so, operational necessity meant that the D-9 was often used in the ground attack and close air support (CAS) roles.The stretched nose fairing needed to accommodate the in-line Jumo 213 earned the D-9 its other nickname: ‘Langenase’ or ‘long nose.’

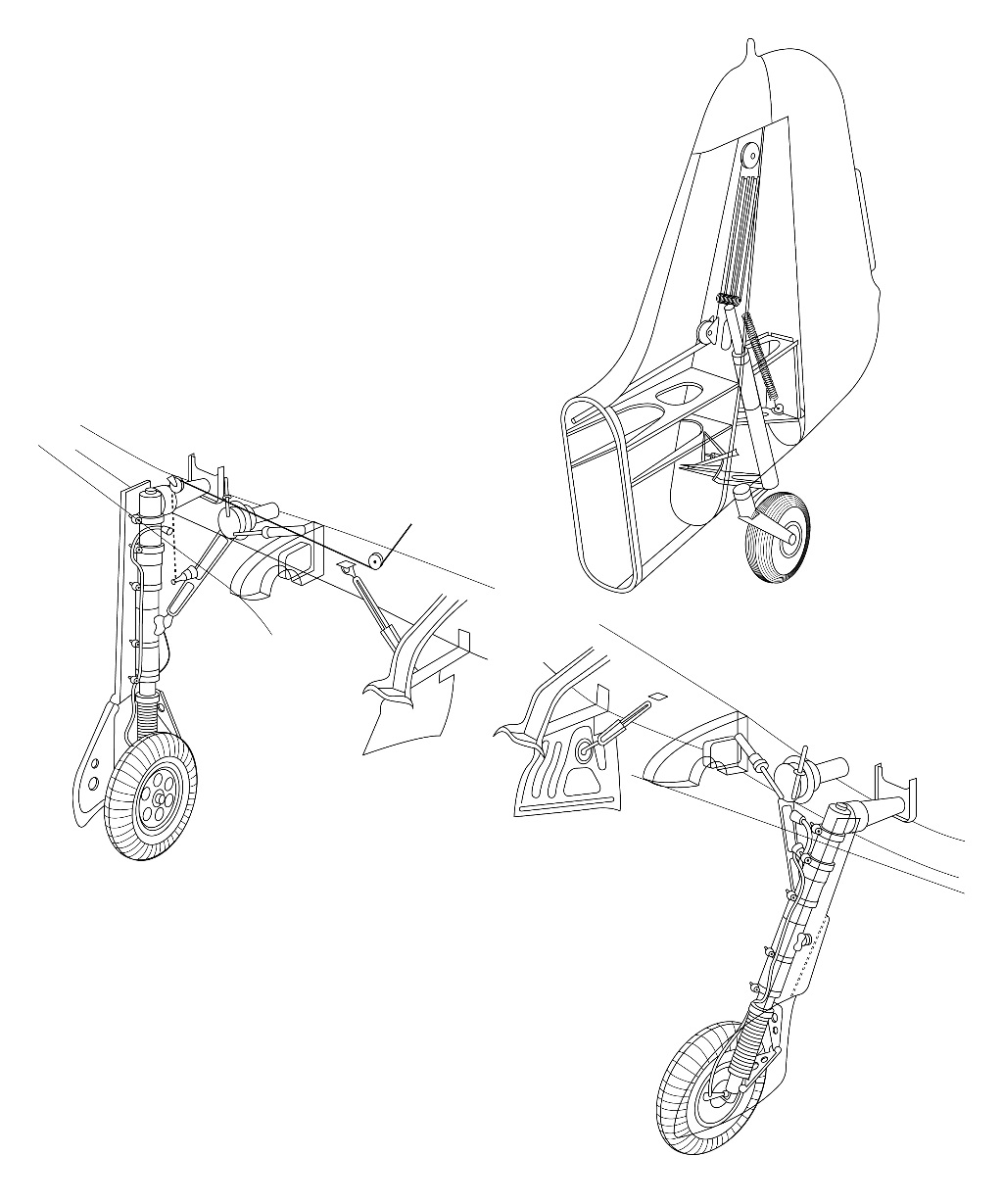

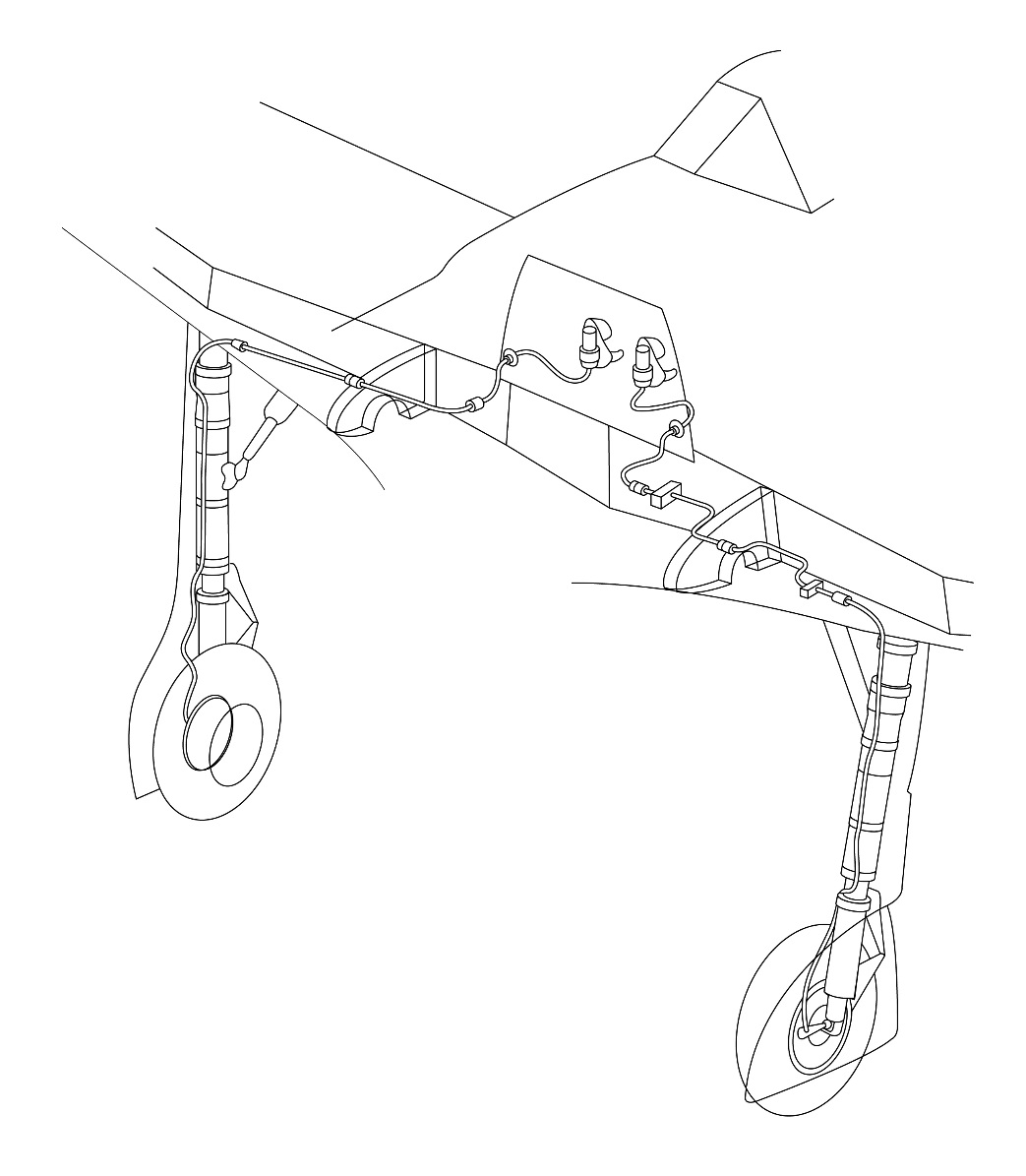

The landing gear is of the inward retracting type, with the main wheels being housed ahead of the front spar when raised. The tailwheel is semi-retractable and is interconnected with the main wheels to synchronize retraction which is achieved by electrical means.

The gear is extended or retracted electrically. A cable attached to the right main landing gear unit also retracts the tail wheel simultaneously with the main gear.

The main gear consists of two shock struts, with a scissors unit connecting the upper and lower shock strut members to absorb torque stresses.

Each main gear strut is operated individually by a drive unit powered by an electric motor mounted on the main spar.

A conventional tailwheel is also provided. It can be rotated 360 degrees and has a centering lock.

The Fw 190 D-9 has hydraulically operated brake shoes on each of the two main wheels. Each has its own hydraulic pump and brake lines.

Each wheel can be braked individually.

The entire system is conventionally operated via rudder pedals.

The Fw 190 D-9 is powered by a Junkers Jumo 213A-1 engine, a 12-cylinder liquid-cooled inverted inline Vee. The Jumo 213 features a single stage, two speed supercharger and an automatic manifold pressure regulator. The engine drives a three-blade constant-speed propeller.

The Junkers Jumo 213 engine comes equipped with a "Bediengerat" Engine Control Unit. It is similar in function to the "Kommandogerat" command device used on BMW-801-powered earlier variants of the Fw 190.

The "Bediengerat" is a hydraulic-electric mechanical multifunction integrator that dramatically simplifies engine control. While in most other contemporary aircraft the pilot had to constantly operate a slew of levers to manage throttle level, propeller pitch, fuel mixture, and supercharger stages, the "Bediengerat" takes the majority of the workload away. The pilot simply has to move the throttle lever to set the desired manifold pressure. The "Bediengerat" takes care of the rest, setting all other parameters to allow the engine to properly operate at the desired manifold pressure, given the current flight conditions.

The gauge used to monitor desired supercharger pressure is the Supercharger Pressure Gauge to the right of the front dashboard labeled ATA.

Additional controls are also available that allow for some Engine Control Unit parameters to be manually finetuned.

The Junkers Jumo 213 engine is equipped with a single stage, two speed centrifugal supercharger with MW-50 Water-Methanol injection into the intake and the aftercooler.

MW-50 (MethanolWasser 50) is a 50-50 mixture of methanol and water sprayed into the Fw 190 D-9's supercharger of, allowing the use of increased boost pressures.

The MW-50 tank has a capacity of 115 liters (85 kg).

The primary effect of the mixture spray is its anti-detonant effect, which is how the increase in boost pressure is achieved.

The secondary effect of the mixture spray is cooling of the engine.

While the primary boost-increasing effects deteriorate with altitude, the secondary cooling effects are still noticeable. Therefore, the MW-50 system can be used to cool down the engine at all altitudes in an event of an emergency.

The boost provided by the MW-50 begins to decrease in power at altitudes above 6,000 meters.

The boost increase provided by MW 50 can be described with the word "incredible".

Turning the system on immediately increases engine power by almost 100 HP due to the fact that a cooler engine can pull in more air. At the same time, turning on the MW-50 enables much higher supercharger boost levels. In optimal conditions, both effects combined increase engine power by a whopping 350…400 HP.

The Fw 190 D-9 has two main tanks, forward (Vorn) and rear (Hinten), both conveniently located below the cockpit floor underneath the pilot's seat. The fuel tanks and the fuel lines are self-sealing. Engine-driven pumps feed the fuel into the engine at a normal pressure of 1 to 2 kg/cm3. There is also an electrical booster pump in each of the two tanks that prevents vapor lock at altitude, provides improved fuel supply and can serve as a back-up in case of main pump failure.

There is also a primer fuel tank built into the rear fuel tank with a capacity of 3 liters.

The tanks have a capacity of 232 liters (172 kg) front (Vorn) and 292 liters (216 kg) rear (Hinten).

The Fw 190 D-9 can also carry an external drop tank under the fuselage with the capacity of 300 liters.