Desarrollado en los años inmediatamente posteriores a la Segunda Guerra Mundial, el MiG-15bis fue un caza de reacción de primera generación diseñado por la oficina de diseño Mikoyan-Gurevich de la Unión Soviética. El MiG-15bis es un caza monomotor con alas en flecha del que se fabricaron más de 15.000 ejemplares. El MiG-15 se hizo famoso en los cielos de Corea, donde luchó contra el F-86 Sabre y otros aviones aliados. Demostró ser un excelente rival para el Sabre, y a menudo era la habilidad del piloto la que determinaba quién llegaba a casa y quién se quedaba colgando de un paracaídas. Con una excelente relación empuje-peso y buenas características de ascenso, el MiG-15bis también estaba armado con dos cañones NR-23 de 23 mm y un único y potente cañón N-37 de 37 mm. No es de extrañar que muchos lo consideren uno de los cazas más mortíferos de la época.

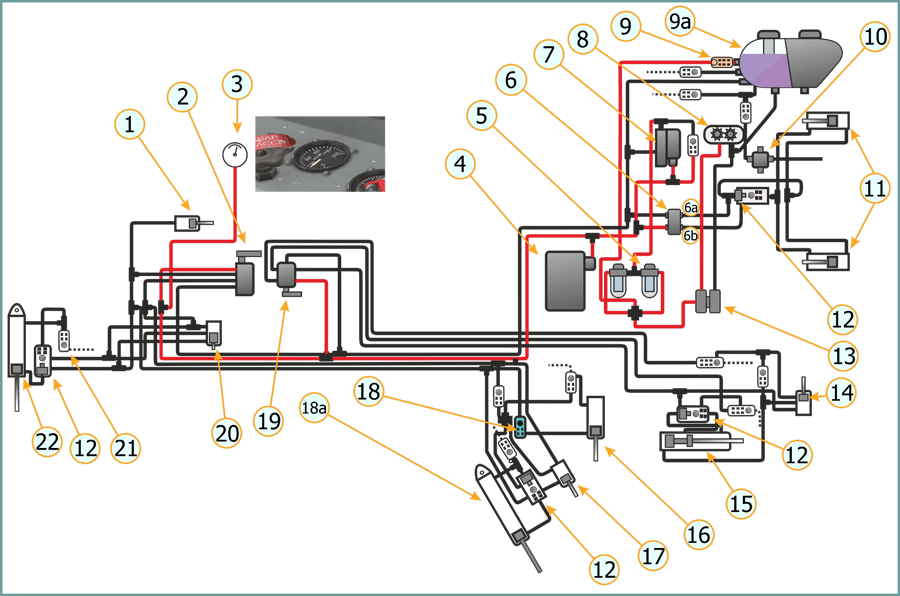

The MiG-15bis is equipped with a 28.5 VDC single-circuit electrical power system. Power sources include a single 12A-30 battery and a ГСР-3000 (GSR-3000) generator with a 3.0 kW power output capacity. Both power sources are connected to a single bus.

Because the airplane is not equipped with an AC power system, each consumer requiring AC power is equipped with an individual inverter (115 V and/or 36 V).

In case of generator failure, the battery supports aircraft flight in daytime and in cloudy conditions for 24-26 minutes or 20-23 minutes at night.

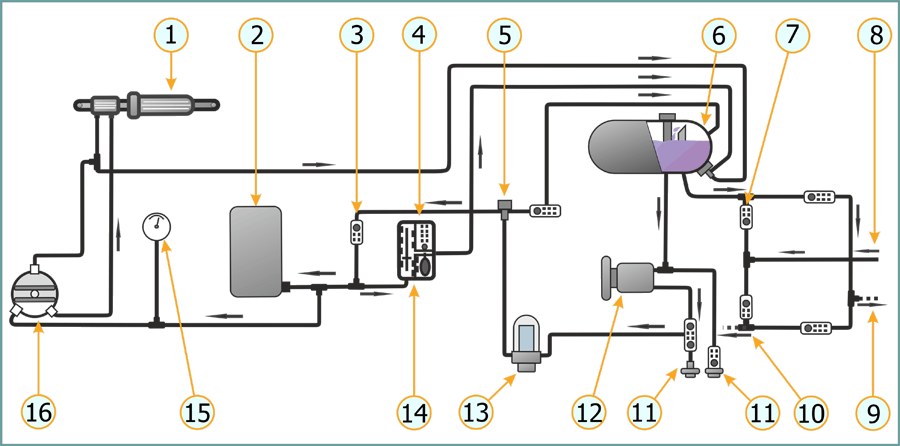

The utility hydraulic system provides:

The lateral control hydraulic system is designed to reduce the stick forces required for lateral flight control (roll). The system is completely independent from the utility hydraulic system (separate hydraulic tank and pump). The system supplies hydraulic fluid to the hydraulic booster under constant pressure to actuate aileron control.

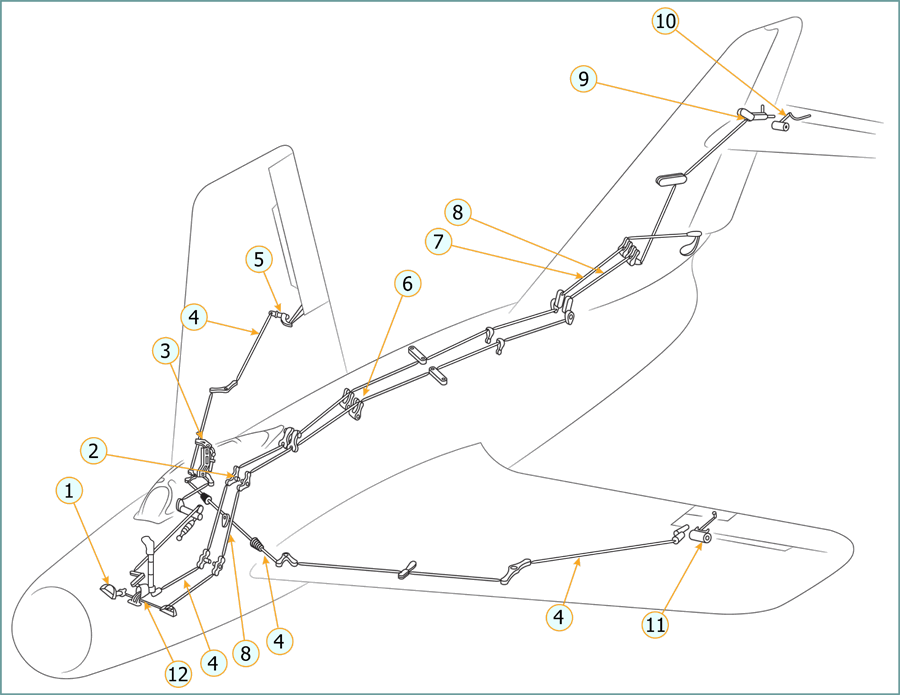

In the 1950s the concept of an aircraft's flight control system included not only controls associated with pitch, roll, yaw, and engine control (stick, pedals, throttle, trimmers), but also flap and airbrake controls.

The flight control system includes cockpit controls, associated control surfaces, and the linkages between them.

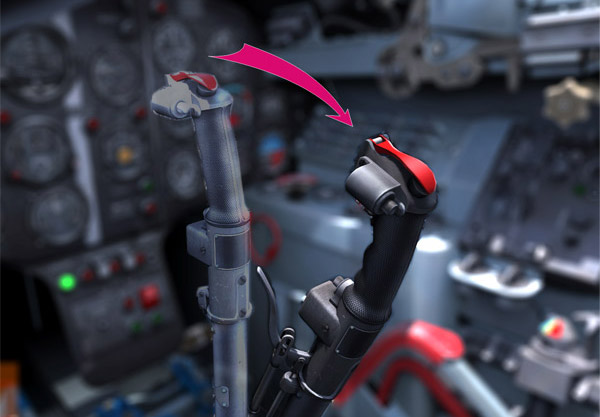

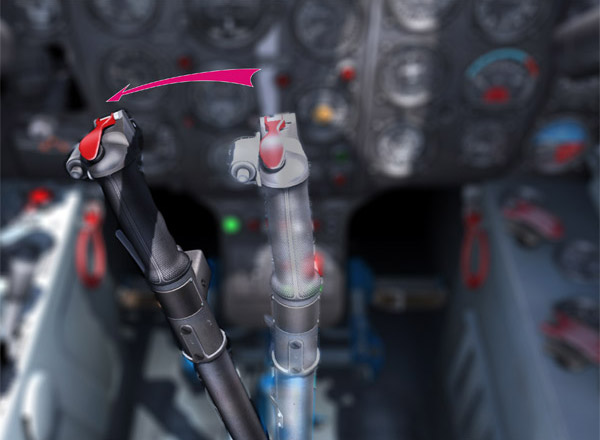

Elevator (pitch) control: accomplished by pushing and pulling the flight control stick forward and aft (pulling aft in the image below):

Elevator trim control: accomplished using the elevator trim control switch on the left side of the cockpit via an electrical trim control motor installed in the stabilizer spar.

Aileron (roll) control: accomplished by deflecting the flight control stick to the left or right (left in the image below):

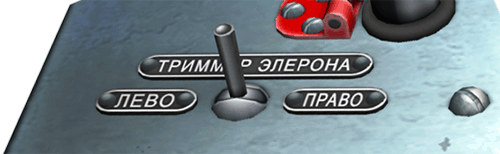

Aileron trim control: accomplished using the aileron trim control switch via an electrical motor installed in the left wing rear beam.

Rudder (yaw) control: accomplished by pushing the left or right pedal (for left or right yaw, respectively) (left pedal application shown in image below):

Forward pedal travel is limited to 29° from the neutral position. At this limit, rudder deflection amounts to 20°.

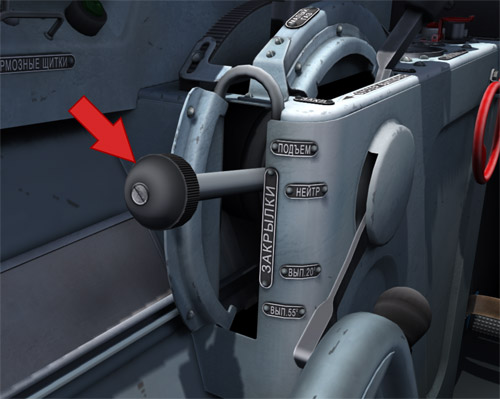

Flap control: accomplished using the flap control handle arranged vertically at the rear of the left cockpit console:

The flaps are installed on the wings between the ailerons and the fuselage. Flaps are extended to their maximum position of 55° when landing. For takeoffs, flaps are set to the intermediate (takeoff) position of 20°.

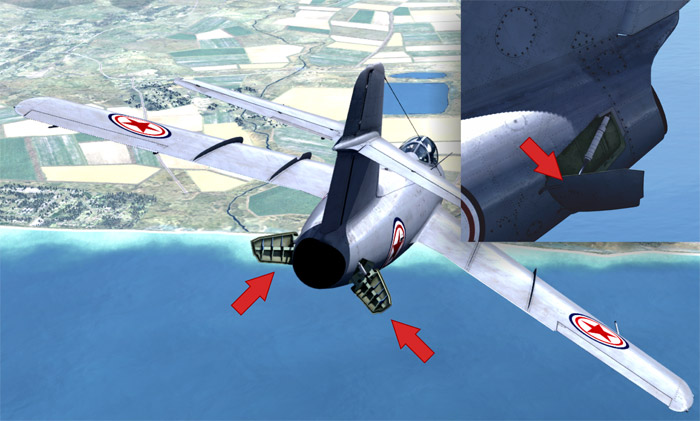

Airbrake control: The airbrake can be extended either by pressing the airbrake button on the control stick (for short use while the button is held down) or setting the airbrake switch on the left cockpit console to the OPEN (forward) position for longer use (for example when diving).

The airbrakes open to an angle of 55°±1°. Movement of the airbrakes from the closed position is indicated by the airbrake caution light on the left cockpit console, which is connected to a microswitch on the right airbrake paddle.