The MiG-15 is a highly-capable clear-weather interceptor and light ground attack aircraft that saw much action in both the Korean and Vietnam Wars. Known as “Fagot” to NATO and “Type 15” to the USSR, it was the first swept-wing jet fighter to come out of the Mikoyan-Gurevich stable in the late 1940s. The MiG-15 served in large numbers during the 1950-53 Korean War, where its maneuverability and high transonic speed made it superior to all UN aircraft except the F-86 Sabre. The MiG-15 is credited with the first ever air-to-air jet kill, downing a USAF F-80C Shooting Star on November 1, 1950.

The DCS variant is the improved MiG-15bis ("second") type, which entered service in 1950 with a Klimov VK-1 engine giving it an effective top speed of Mach 0.92 (685 mph)

A powerful 37mm autocannon in the lower right fuselage (40 rounds total) and 2 × 23mm autocannon in the lower left fuselage (80 rounds per gun, 160 rounds total) give the MiG-15bis tremendous punch. In the secondary light ground attack role, the Fagot can also carry 100 kg bombs or rocket pods on its twin underwing hardpoints.

On 23 October 1951, 56 MiG-15bis intercepted nine B-29 Superfortresses escorted by 34 F-86 Sabres and 55 F-84E Thunderjets. Despite being outnumbered, the Soviet-piloted MiG-15s shot down/and or seriously damaged eight B-29s and two F-84Es, losing only one MiG in return, leading the Americans to call that day "Black Tuesday".

Some 18,000 MiG-15s were built and served in every nation under the Soviet sphere of influence during the Cold War and on into the 21st century. Battle the equally superb DCS: F-86 Sabre and see who comes out on top.

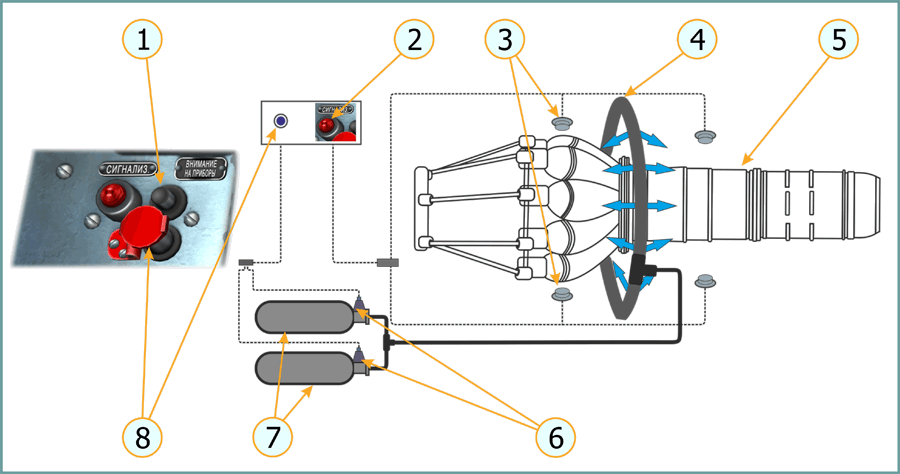

The fire extinguishing system is designed to extinguish a fire in the fire hazard zone of the engine, i.e. the area where damage to the engine may lead to an open flame. This zone encompasses the area from the rear of the combustion chambers to the compressor turbine.

The fire extinguishing system includes:

In case of a fire and temperature reaching 120 – 140°C in the engine compartment, the fire detectors signal a warning and the FIRE warning light illuminates in the cockpit. To active the fire extinguishers, the pilot presses the activation button for fire the squibs of the extinguisher bottles. Firing the squibs perferates the bottle cap membrane and releases the gas through the extinguisher line into the manifold, where it is dispersed around the fire hazard zone of the engine to extinguish the fire.

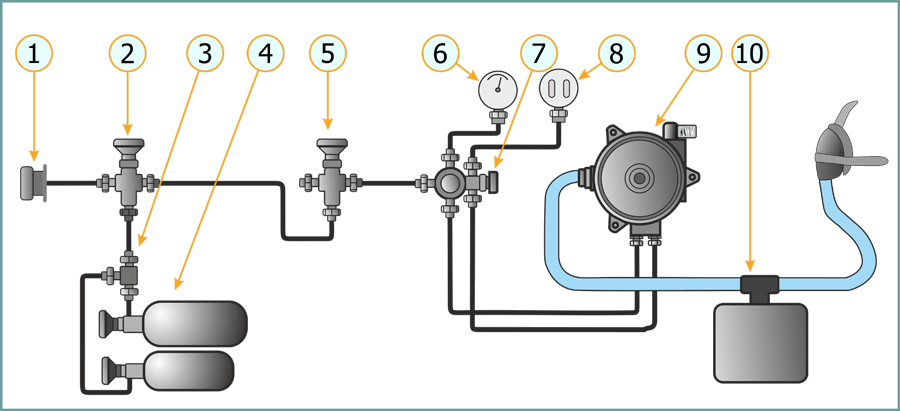

The oxygen supply system is designed to provide the pilot with required oxygen supply in flight. The system consists of oxygen bottles (tanks), tubing lines, pressure gauges, KP-14 oxygen regulator, KP-15 parachute oxygen set.

Oxygen supply system operation

Oxygen is maintained at a pressure of 150 kg/cm2 in the bottles (4). Under normal use, oxygen from the bottles flows to the charging valve (2) via a triple adapter, which connects the bottles with the onboard charging connector (1) for charging or with the onboard supply line for pilot use. From the charging valve, oxygen flows to the onboard supply valve (5). The supply line then leads to the KR-14 pressure relief valve (7), from which one of the lines leads to the pressure gauge (6), located on the left side of the instrument panel, while the other one leads to the KP-14 oxygen regulator (9).

The KP-14 regulator supplies the proper mixture of oxygen and air at all times, automatically supplying positive pressure-breathing at high altitudes. As altitude increases, the percentage of oxygen in the mixture increases as well.

A hose and oxygen mask are attached to the regulator. The regulator is connected to the IK-14 oxygen flow indicator (8). The KR-14 pressure relief valve decreases oxygen pressure to 2-3 kg/cm2 as it directs oxygen to the regulator. In the regulator, pure oxygen is mixed with surrounding cockpit air. The pilot breathes surrounding pressurized cockpit air up to a cockpit (pressurized) altitude of 2000 m, i.e. the pilot is not supplied with oxygen from the tanks by the oxygen supply system. At altitudes between 2000 and 8000 m, the percentage of oxygen in the regulator mixture begins to increase. At cockpit altitudes over 8000 m, the pilot is supplied with 100% oxygen.

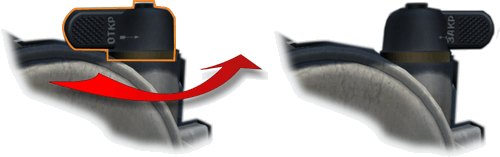

Operation of the KP-14 oxygen regulator requires opening the diluter valve:

The simulation assumes the pilot is always wearing the oxygen mask. Failure to open the diluter valve means the pilot will be starved of oxygen and may begin to lose consciousness in 30 - 40 seconds.

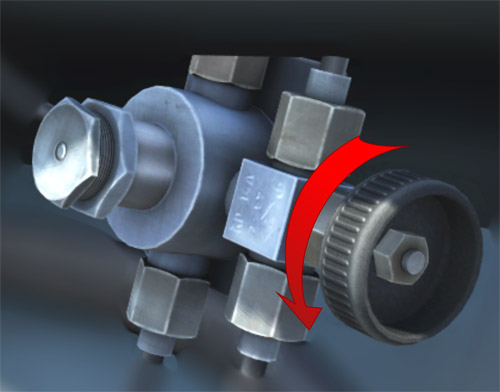

In case of a fire or smoke in the cockpit at high altitudes, use of emergency oxygen is recommended. To enable emergency oxygen flow, turn the emergency oxygen supply valve on the KR-14 pressure relief valve fully left (counterclockwise).

In case of cockpit depressurization at altitudes of up to 12000 m, the oxygen supply system provides a sufficient supply of oxygen to allow for a descent to safe altitudes. Depressurization at altitudes above 12000 m is fatal.